Pulsed Plasma Deposition (PPD)

PPD is a revolutionary new physical vapour deposition (PVD) technique proved to deposit thin films of numerous materials such as oxides, complex oxides, nitrides, carbides, carbon based films, semiconductors,etc.

The deposition of thin films using PPD is done by ablation of a target material using a fast pulse of electrons (100 ns) and the material is deposited on the substrate. Ablation by the fast electron beam causes the formation of a hot, dense, and high- velocity plasma. The salient features of the company's PPD system are a wide dynamic range of deposition rates (0.01 nm/s to 5 nm/s) and a wide range of operation vacuum conditions (10-2 mbar to 10-5 mbar) making it possible to reach the most diverse and suitable conditions of growth.

The chemical composition of the target is transferred to the substrate by a supersonic highly energetic plasma giving rise to thin films of materials otherwise impossible to grow with conventional PVD and CVD techniques. The PPD process is a low temperature process with unparalleled possibilities for the growth of hetero-multilayer structures and for the deposition on delicate surfaces.

PPD Characteristics

| Energy (J) | >2 |

| Growth rate (nm/s) | 0.001-5 |

| Repetition rate (Hz | 1-30 |

| Beam power density (MW/cm2) | 4-300 |

| Energy efficiency | >30% |

| Scalability | The first multigun system with four Gen II Guns is in operation since 2007 |

| Suitable for transparent materials | Yes |

| Suitable for plastic (low Tg) substrates | Yes |

The process of ablation by the interaction of a ns pulse of electrons with matter has been historically defined as Pseudo Spark Ablation, Channel Spark Ablation, and Pulsed Electron Deposition.

Our definition of it as Pulsed Plasma Deposition (PPD) is deeply based on our extensive study of the process itself (see references).

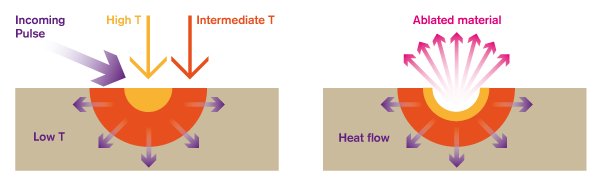

The large amount of electronic energy delivered by the PPD source to the target material forms a non-equilibrium temperature distribution and eventually the material explodes (ablation by explosion) forming a plasma.

Plasma is the state of matter, which corresponds to the highest energy density (temperature) of matter. A flux of plasma composed of ions, electrons, atoms and particles is directed to the substrate at supersonic speed.

The process is different from the ablation caused by the interaction of matter with photons ( i.e. Pulsed Laser Deposition - PLD) since the plasma is a distinctive feature of the source (electrons vs photons).

In our case the plasma plays a significant role in the ablation (and deposition processes) since, in order to achieve the electron energy density required for ablation, the electron beam needs to be composed by a sufficient number of ions for charge compensation.

In order to achieve the largest energy density at the target it is therefore crucial to generate an electron beam with some plasma in order to eliminate the mutual repulsion of electrons and not a pure electron beam.

This is the reason why it is appropriate to use the term "Plasma" as the second word when defining the technique, while the third word "Deposition" indicates our final goal, i.e. to deposit a film of some material on a substrate.

The deposition of various films with different properties is the key element for producing new materials for a large number of applications. Our overall aim is to develop the PPD as a tool for the industry and for research allowing to deposit a vast array of materials.